How to Choose the Right Metal Laser Cutting Machine Supplier for Your Business

- jinanhengcheng

- Apr 17

- 6 min read

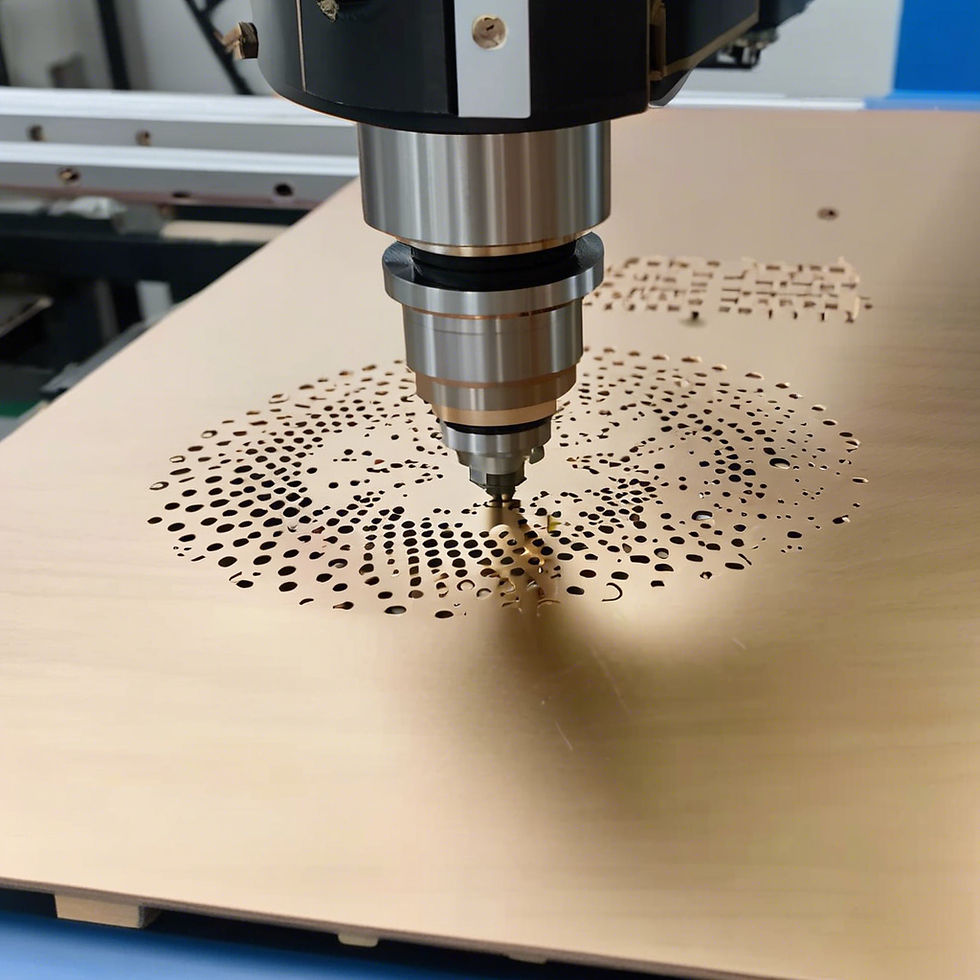

In today’s fast-paced manufacturing environment, investing in a high-quality metal laser cutting machine is no longer a luxury—it’s a necessity. Whether you're operating a fabrication shop, an automotive parts production line, or a custom metal art business, the precision and efficiency offered by laser cutting technology can significantly boost your productivity. However, choosing the right supplier for these machines is just as important as selecting the machine itself. An experienced and reliable supplier can ensure consistent performance, timely support, and lasting value for your investment.

Understand Your Business Requirements First

Before beginning your search for a supplier, it is essential to have a clear understanding of your own business needs. This means taking a deep dive into the type of metal materials you work with, the thickness range you usually cut, your required production volumes, and your level of automation preference.

For instance, a supplier that specializes in machines for light-gauge sheet metal may not be the best fit if your operations involve thick, heavy-duty metal plates. Similarly, if your business requires complex cuts with minimal margins of error, then fiber laser cutting machines with high precision and repeatability are crucial.

Identifying these key parameters will not only narrow down your supplier options but also ensure that the machine you purchase will integrate seamlessly with your current and future production needs.

Evaluate the Supplier’s Industry Experience

Experience matters, especially when it comes to high-tech industrial equipment. A supplier who has been in the metal laser cutting business for several years brings a wealth of knowledge and insight that newcomers may lack. They’re more likely to understand the specific challenges that businesses face and can offer tailored recommendations to match your requirements.

Moreover, experienced suppliers have usually dealt with various machine brands and configurations. They understand how different systems perform in real-world scenarios and can provide valuable guidance on what will work best for your specific applications. Their long-standing presence in the market also signals credibility and stability—two important factors when committing to a long-term investment.

Check the Quality and Origin of the Machines Offered

The quality of the laser cutting machine is directly tied to the supplier’s credibility. A reputable supplier will be transparent about the machine's components, manufacturing origin, and the standards followed during production.

It's important to know whether the machine parts—such as laser sources, servo motors, controllers, and lenses—are sourced from reliable global brands or are in-house manufactured. High-end components from companies like IPG, Raycus, or Precitec generally promise better performance and longevity.

In addition, understanding the machine’s country of origin can also play a role in your decision. Machines made in Germany, Japan, or the United States are often known for engineering excellence, while machines manufactured in China or other Asian countries might offer cost advantages with decent quality. A good supplier will offer transparency about all these details and help you weigh quality against budget.

Assess Technical Support and After-Sales Service

Buying a metal laser cutting machine is a significant capital investment, and ongoing support is essential to get the most out of it. Before signing a deal, evaluate the supplier’s service capabilities.

Do they offer on-site installation and training? Is their customer service team responsive and technically competent? Do they provide maintenance contracts or extended warranties? What is their typical response time in case of a machine breakdown?

A supplier with a well-organized service infrastructure ensures that your machine runs with minimal downtime. Ideally, the supplier should offer local or regional service teams, online troubleshooting support, spare parts availability, and preventive maintenance plans. This kind of robust after-sales support can save your business a lot of time, money, and operational headaches in the long run.

Inspect Customer Reviews and References

Reputation speaks volumes. One of the best ways to evaluate a metal laser cutting machine supplier is by listening to what their existing clients have to say. Ask the supplier for client references, and follow up with those contacts to learn about their experience.

You can also look at online reviews, testimonials, and case studies. Be on the lookout for any red flags like complaints about product quality, unfulfilled promises, or poor customer service. A consistently positive track record indicates a trustworthy supplier who delivers on their commitments.

Suppliers who have experience working with businesses similar to yours are even more valuable, as they are likely to understand your industry’s specific challenges and goals.

Evaluate Product Range and Customization Options

A good supplier is not limited to offering one or two models. Instead, they should have a broad range of metal laser cutting machines suited for various cutting needs, metal types, and production scales. Whether you need a basic model for prototyping or a high-speed automated solution for mass production, the right supplier will offer flexible options.

Additionally, if your business has unique needs, such as customized bed sizes, rotary attachments, or tube cutting capabilities, your supplier should be able to accommodate them. A willingness to customize demonstrates that the supplier is focused on helping you solve problems, not just selling standard equipment.

Consider the Supplier’s Global Reach and Export Capability

If you are planning to import a machine from another country, it’s essential to work with a supplier who has a strong export background. An experienced exporter will be familiar with shipping logistics, export documentation, and compliance with international standards.

This is particularly important if you’re located in a country with specific import regulations or require particular certifications like CE, ISO, or FDA (depending on the application). The right supplier will make the import process smooth by handling freight coordination, customs documentation, and insurance, ensuring that the machine arrives safely and on time.

Compare Pricing with Value, Not Just Cost

While price is always a factor in any major purchase, it should never be the only one. Cheaper machines might seem attractive at first glance, but they often come with compromises in quality, support, and durability.

Instead of focusing purely on upfront cost, assess the overall value that a supplier provides. This includes machine quality, warranty coverage, training, service support, availability of spare parts, and machine upgradeability. Investing a little more initially for a higher-quality machine and better service can save you thousands in the long term.

A credible supplier will be upfront about all costs involved—machine pricing, installation, training, delivery, taxes, and potential future upgrades. Transparency in pricing is a hallmark of a professional supplier.

Inspect the Facility or Request a Virtual Tour

If possible, visiting the supplier’s facility can provide a wealth of insights. You can inspect how the machines are assembled, the quality control processes in place, and the professionalism of the technical team. If a physical visit is not feasible, request a virtual factory tour or a live demo through video conferencing.

Seeing the equipment in action, even virtually, can help you evaluate the build quality, user interface, cutting speed, and finish of the final product. It also shows the supplier’s confidence in their technology and willingness to be transparent.

Look for Continuous Innovation and R&D Commitment

The metal laser cutting industry is evolving rapidly, with advancements in speed, energy efficiency, automation, and AI integration. Choosing a supplier that invests in research and development ensures that your business stays future-proof.

Ask potential suppliers about their R&D initiatives, recent innovations, and how frequently they update their machine technology. Suppliers who innovate regularly are more likely to offer long-term solutions and software upgrades that keep your machine competitive.

Check for Training and Educational Resources

Purchasing a metal laser cutting machine involves more than just buying hardware—it also includes training your staff to operate it effectively. A good supplier should provide comprehensive training for your team, either at your site or at their training center.

Additionally, look for suppliers that offer manuals, video tutorials, software guides, and regular webinars. These resources can be incredibly helpful for onboarding new employees or troubleshooting minor issues independently.

The more knowledgeable your staff is about the machine, the more efficiently your production line will run, and the less dependent you'll be on external service calls.

Trust Built Through Relationships

At the heart of every successful business deal lies trust. When choosing a metal laser cutting machine supplier, look for signs that the supplier values long-term partnerships over one-time sales. Do they take the time to understand your business? Are they available to answer questions without pushing for a hard sell? Are they responsive, friendly, and informative?

A supplier who focuses on relationship building will be a valuable ally throughout the life of your equipment—from installation and training to service and expansion. This kind of partnership can help you scale your operations with confidence.

Conclusion

Selecting the right metal laser cutting machine supplier is a decision that affects the future of your production capabilities, your costs, and your competitiveness. It's a blend of technical fit, service reliability, supplier transparency, and long-term value. By carefully evaluating suppliers on these fronts and aligning them with your business objectives, you position your company for sustained growth and operational excellence.

Don’t rush the process. Take your time to research, ask the right questions, and request demonstrations. In the world of manufacturing, the right supplier is not just a vendor—they are a strategic partner that can help you stay ahead in a competitive market.

Comments